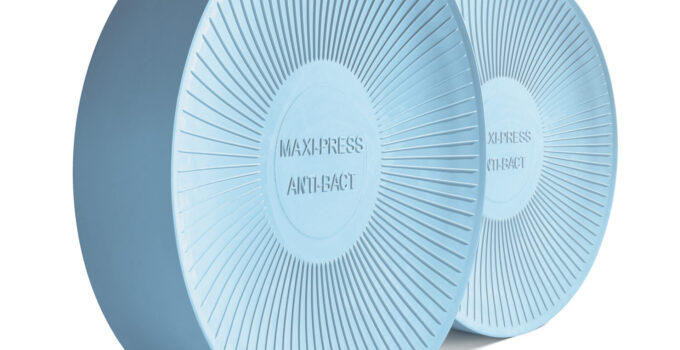

Fulda, January 1, 2021 ‐ MAXI‐PRESS presents the world’s first antibacterial membrane for all common water extraction presses in laundries from the start of the year. The manufacturer of water extraction membranes developed the new “ANTI‐BACT” membranes to permanently reduce the risk of bacterial contamination in laundries. The ANTI‐BACT membranes are made of an antibacterial material ‐ tested by the German Hohenstein Institute ‐ which actively prevents the formation of bacteria on the membrane surface.

The ANTI‐BACT membranes ensure more hygienic linen. The linen is protected during the pressing process from possible bacterial contamination originating from the membrane surface. The linen is thus optimally prepared for further processing. ANTI‐BACT actively prevents the formation of organic deposits on the membrane and is designed to give strong effectiveness against bacteria forming. This is especially significant for laundries that offer textile services to strict standards, for example the German RAL Quality Mark for hospitals and care facilities. Working with ANTI‐BACT membranes will significantly lower the maintenance effort required to meet any strict hygiene standards.

The new ANTI‐BACT products combine the germ reducing properties with all known advantages of the previous EASYFIX membranes from MAXI‐PRESS and are given the suffix “AB”. ANTI‐BACT or the special material in combination with the membrane is a certified and protected product of MAXIPRESS Elastomertechnik GmbH. The ANTI‐BACT membranes are produced directly by the company using a new production plant that was put into operation especially for this product series. There, the world market leader for water extraction membranes compresses the special material for the antibacterial membranes with a pressure of 2,000 tons. “In order to be able to implement this revolutionary product, we have made targeted investments in our machinery,” says Tim Zaiser, Managing Director of MAXI‐PRESS Elastomertechnik GmbH. “We have been working on the development of ANTI‐BACT membranes for a long time ‐ well before COVID‐19”.

The Hohenstein Test Institute has confirmed the sterility of the ANTI‐BACT membrane with its test seal. After extensive testing, the product was certified with the “Hohenstein Quality Label ‐ Antibacterial”. The tests were carried out in accordance with recognized standards, for which accreditation is available from the Deutsche Akkreditierungsstelle GmbH. The test basis was to ISO 22196:2011‐08 standards (Plastics ‐ Measurement of antibacterial activity on plastic surfaces) with the test germs “Staphylococcus aureus” and “Escherichia coli”.

The antibacterial effect of the new ANTI‐BACT membranes is unlimited and to make life even easier, the ANTI‐BACT is available in the EASYFIX membrane design with built in fixing ring for all common water extraction presses. The EASYFIX membranes from MAXI‐PRESS can be replaced much easier and faster than standard membranes.